Equipment

Equipment for materials synthesis

Floating-zone furnace:

There are two distinct advantages in using the floating-zone technique for crystal growth. First, since no crucible is needed during growth, crystals produced by this method can be very clean. The impurity level in crystal can be reduced down to ~50 ppm. Second, very large crystals can be grown with this method. Large-size crystals are very useful for certain experiments such as neutron scattering.

High-temperature furnaces (up to 1700 C)

Glovebox for meterial synthesis

Glovebox for electrochemical intercalation

Equipment for material characterization

Rigakut Model D/Max 2200/PC X-Ray diffractometer

Polishing machine and diamond saw

Equipment for low temperature measurement

A Physical Property Measurement System (PPMS, Quantum Design)

Equipped with an EverCool dewar, 9T magnet, AC transport measurement probe, specific heat measurement probe, AC/DC magnetization measurement probe, and sample rotator for transport measurements.

Magnetic Property Measurement System (MPMS, SQUID, VSM, Quantum Design)

He3 cryostat with the base temperature of 0.3 K

Other shared facilities and resources

Cleanroom facilities

Equipped with an sputtering coating system, an electron beam evaporator, an Argon ion milling system, a spin coater, and a mask aligner.

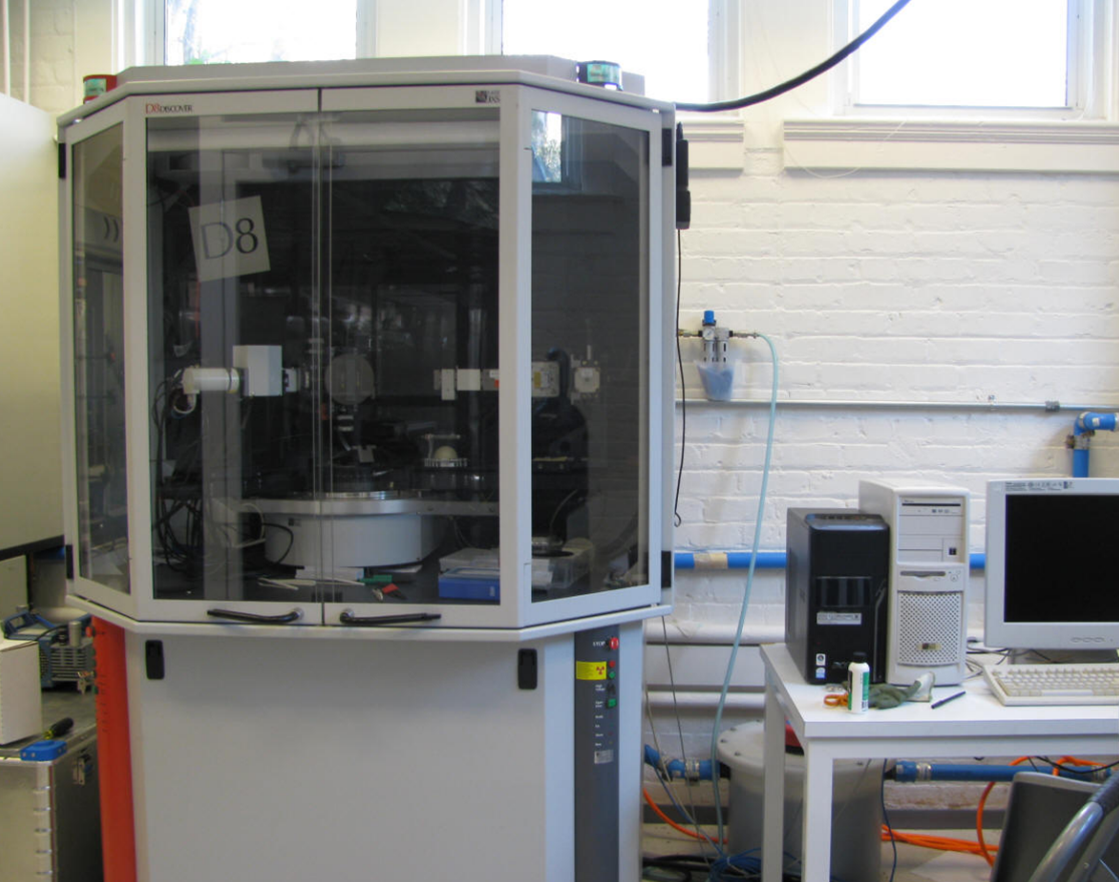

Bruker D8 Single Crystal X-Ray diffractometer

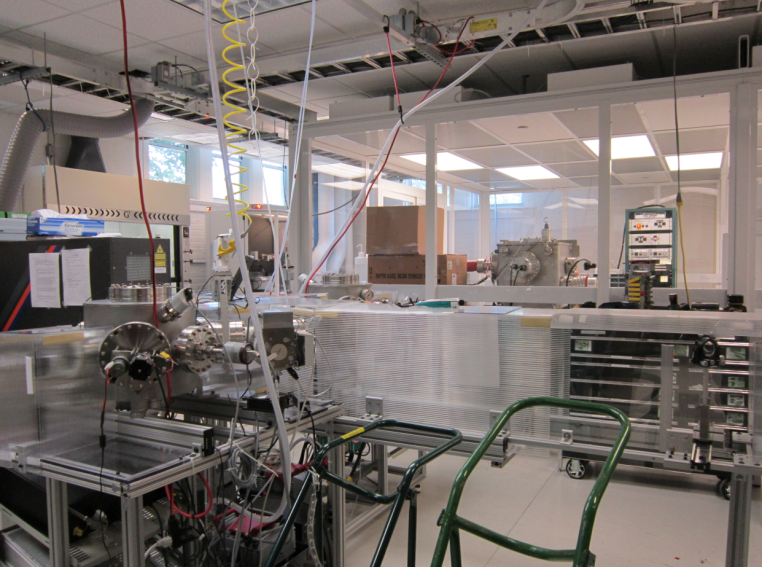

Pulse Laser Deposition system for film growth